Research & Development Technical Office

Our technical resources and official team allow us to develop projects from paper design to final execution as per project or necessity of costumer.

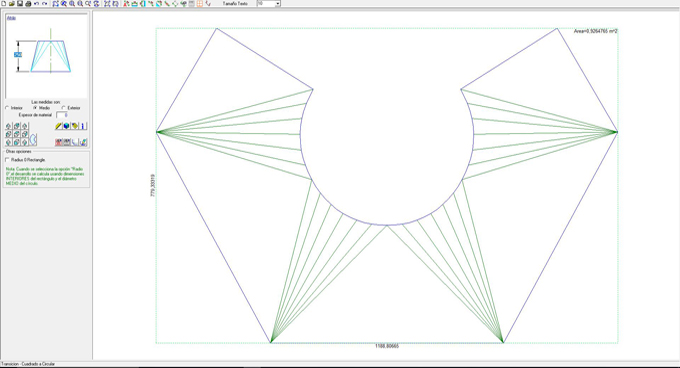

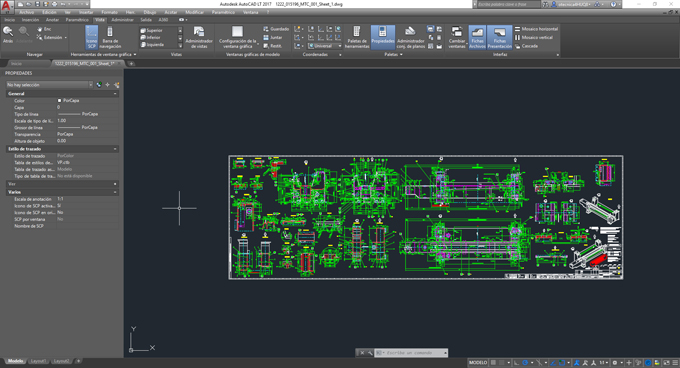

We perform all kinds of exploded views using 2D (AutoCAD) and 3D (SolidWorks) software tools along with all the latest technology. We cut the complete set starting from plans both provided by the customer and made by our technical office. We calculate the deformations and contractions that may be generated in the weld, as well as the necessary excesses for final machining. In this way, we reduce errors to a minimum in our manufacturing process.

On the other hand, we review each and every request of our client’s as on specifications to supply the products with correct safety measure applicable as per current regulations. We review:

- Specification of the necessary materials.

- Specification of welding procedures.

- Welding qualifications required.

- Non-destructive testing (NDT) procedures.

- Heat treatment procedures.

- Quality control agreements.

- The obligation of inspections and testing.

In addition, the R&D Technical Office department has a Certified Professional Project Manager (CAPM) from the Project Management Institute (PMI), which allows us to approach each project with the maximum guarantees of success.